The Intricacies and Significance of Diecasting in Trendy Manufacturing

The Intricacies and Significance of Diecasting in Trendy Manufacturing

Blog Article

Diecasting is a diverse and extensively used manufacturing method which involves putting molten metal into a mold cavity at the pressure of a high. It is extremely efficient in the production of large amounts of metal parts that are complex that have excellent accuracy in dimensional measurement and smooth surfaces. Diecasting's process, the materials and techniques of diecasting are vital to a variety of industries, and it is an integral part of modern manufacturing. The article examines the basic principles of diecasting and its advantages as well as its numerous applications in the industry.

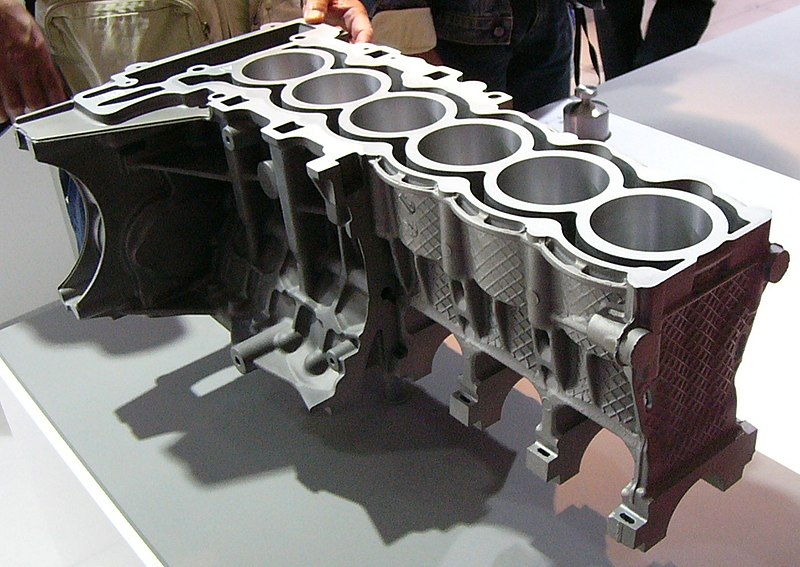

Diecasting starts with the creation of an mold, also known as a die, which is typically made from toughened steel. The mold is constructed for the extreme temperature and pressures that are involved in the process. When the mold is finished, molten metal, usually an alloy of aluminum, magnesium, zinc, or copper is heated to a liquid state and then injected into the mold cavity with high pressure. The pressure will remain constant until the material has solidified, insuring that the solidified metal completely fills the mold with fine parts and walls that are thin. After the metal has cooled and has solidified, the mold is removed and the completed piece is released. This process allows for superior precision and consistency in the production of metal components.

One of the biggest benefits of diecasting is its efficacy in production of large quantities. Once the dies are created it is possible to have the process repeated many times, with little variation between parts. The repeatability is crucial in industries that require large quantity of consistent components. Additionally, diecasting is renowned for its high efficiency. Diecasting produces less waste compared to other techniques for forming metal, as any excess metal is able to be reused and recycled. This not only reduces cost of materials but also helps to promote sustainable manufacturing practices. The speed and efficiency of diecasting make it the ideal alternative for the production of large volumes of pieces quickly and continuously, ensuring that manufacturers can keep to strict production deadlines and demand from the market.

Diecasting can also produce products with exceptional mechanical properties. The rapid cooling of the liquid metal that is formed during the casting process creates fine grain structure that increases the strength and durability of the final product. This makes diecast components particularly appropriate for uses that require the highest level of performance and dependability. As an example, in the automotive industry Diecast components are utilized for transmissions, engines, and structural elements, where their strength-to-weight ratio is critical for safety and vehicle efficiency. In the aerospace field diecast elements contribute to developing lightweight but solid structures, which are crucial to optimizing the efficiency of fuel and performance. To obtain added information kindly head to Senadiecasting

Diecasting's capabilities extend to a wide array of applications across different sectors. For instance, in the automobile industry, diecast components are integral in the building of transmissions, engines, and structural parts, contributing to the production of lightweight, fuel-efficient cars. For electronics Diecasting is employed to make heat sinks connectors, and housings making sure that the proper thermal management is in place and the durability of electronic devices. The industry of consumer goods is a beneficiary of diecasting, having applications that range from kitchen appliances to power tools and toys. Diecasting's versatility to different metals, as well as its capacity to make parts with complex designs makes it suitable for numerous uses, all benefiting from the distinct benefits that diecasting provides.

Diecasting is a sophisticated manufacturing process that combines precision, efficiency and versatility. The capability to make intricate, high-end parts that possess superior mechanical properties makes it useful in a variety of industries. Diecasting's efficiency when it comes to mass production, with its cost and material advantages, demonstrates its significance in the modern world of manufacturing. Since industries will continue to need quality and reliability components that are high-performance that are durable and reliable, diecasting will be a cornerstone technology, driving advancement and the creation of advanced products that meet the constantly changing demands of the market. By its continual advancement and use diecasting illustrates the interplay between engineering expertise and manufacturing proficiency.